I can blow chips off with my air hose, cut wood or whatever without getting chips on the nice oily ways. And, with the vinyl sheet hanging close by on the left, chips hit the sheet and drop neatly to the floor when I puff them away from the work.

Rubber Sheeting

© Frank Ford 2004; Photos by FF

A couple of years ago I was "double-shipped" on some 1/16" thick soft Neoprene rubber sheeting. So with something like 50 feet of it on a roll, I've spent some time figuring uses for it. It turned out to be way too flexible for tool drawer liners - it would bunch up every time I closed the drawers as the tools shifted.

Here's one use that made me glad I had the stuff lying around the shop. I added estra big rubber shrouds around all the ways and the table of my mill:

I can blow chips off with my air hose, cut wood or whatever

without getting chips on the nice oily ways. And, with the vinyl

sheet hanging close by on the left, chips hit the sheet and drop neatly

to the floor when I puff them away from the work.

I plop my share of tools, bits, chucks and pretty much everything else on the mill table. Now I protect my mill table from scars by simply laying a sheet of the Neoprene on the table:

I keep the sheet in place with my little magnetic holders.

The rubber sheet keeps chips off the table, too.

Speaking of swarf protection -

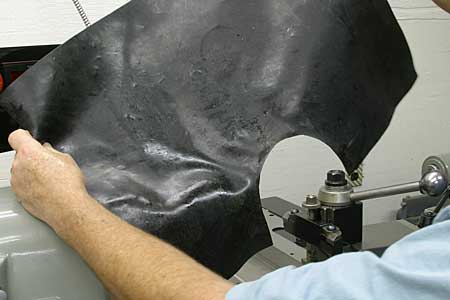

I cut a big hunk of rubber sheet to drape over the entire lathe carriage, with a little cutout for the compound:

As you can see, way lube, cutting oil and the kerosene I use for cleanup all attack the rubber slightly. Turns out that's not been any problem at all. In fact, it makes the rubber even more limp so it lays right were I put it, just like a piece of cloth, and never gets in the way:

(Well, hardly ever. . .) Three of my little magnetic holders keep it in place, tucked right up against the compound, where it can keep swarf from migrating into the works.

And, I can pull off the magnets, pick up the rubber and dump a big load of chips with ease: