Speedometer Cable End

© Frank Ford 2008; Photos by FF

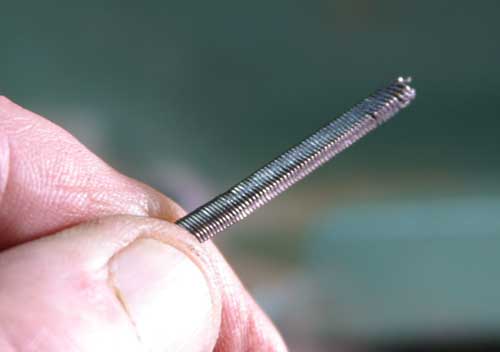

One thing speedometer cables seem to have in common is the square end that's formed by squishing the cable into that shape. Recently my pal, Brian, was replacing the speedometer cable on his motorcycle only to find that the correct length was no longer available. So, with the input from Home Shop Machinist Forum, I set about making a simple die to do the job.

I grabbed a likely

piece of 1/2" thick cold rolled steel scrap

and set it up in my milling machine vise, using a 45 degree angle block to

align it. Once I had it clamped down, I brought a 1/2" end mill over to just

touch the surface. Brian had measured the square end at mighty close

to 0.100" across the flats. So, I simply advanced the X-axis

exactly 0.100" as I milled a V-groove in the 2" wide stock:

You can just see the angle block at the right, under the stock. Yes, the

stock does stick up kinda high, but I was only milling a small V-groove, and

I took it easy to avoid vibration.

A quick visit with Mr. Band Saw to cut the piece off:

And a second cut to split the die into two halves:

OK, that's all the stuff I did in my home shop.

The rest happened at my shop at work. There, we have a Grizzly "wood mill" and on it, a 4" milling vise. It's by far the strongest vise in the house - we're a guitar repair shop, after all. So Brian and I set about mashing his new speedo cable with that vise.

I used a pair of magnets to hold each die half in position in the vise:

It takes a hard squeeze

to shape this stuff, so we worked slowly, me feeding the cable in about

1/32" at a time, and Brian cranking down on

the vise as we went along:

Success:

The end could be neater, but hey, it works.

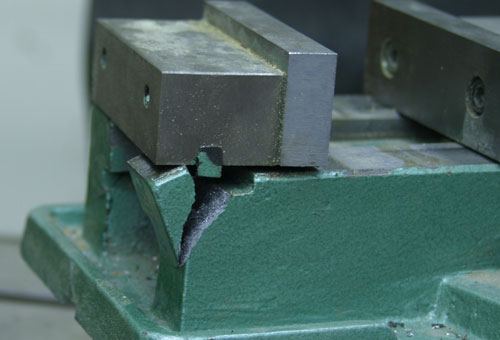

Whoops - a quick update. The next day, Brian decided to resquish (is that a real word?) the cable end, and leaned all of his 160 lb. self on the regular vise handle, with this surprising and painful result: